Informational Charts

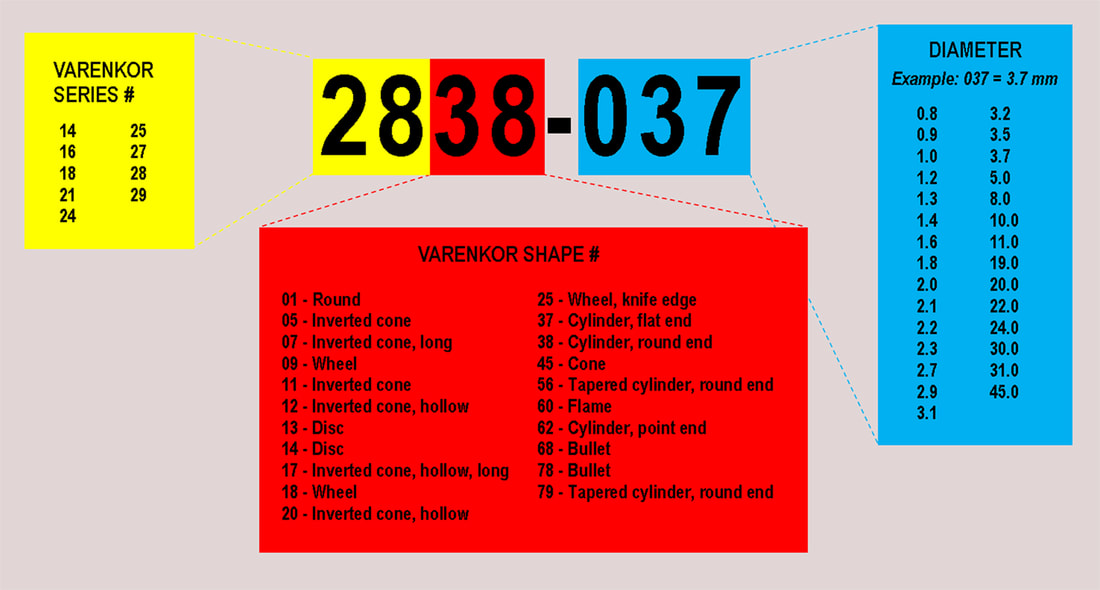

What do the numbers mean?

Series Usage Recommendation Chart

Series |

Description |

Grit Size |

Binder Strength |

Recommended Uses |

X Fine |

600-800 |

Soft |

Pre-polish, recommended to use with water to avoid black marking |

|

Fine |

325-400 |

Medium |

Fine detailing on glass, porcelain, Zirconia and metals |

|

Medium |

200-270 |

Medium |

Medium detailing on glass, porcelain, Zirconia and similar |

|

Coarse |

120-140 |

Medium |

Coarse grinding on glass, porcelain and similar |

|

All Material |

170-200 |

Medium |

All material, coarse on glass, less coarse on metals |

|

Fine, Medium |

170-200 |

Hard |

Fine-Medium grinding on semi-precious alloys, gold, silver, gem stones |

|

Coarse |

120-140 |

Hard |

Coarse grinding on semi-precious alloys, gem stone and quartz |

|

Medium |

170-200 |

Hard |

Medium grinding on harder alloys, nickel chrome, chrome cobalt, stainless steel, iron |

|

Very Coarse |

80-100 |

Hard |

Very coarse for bulk reduction of chrome cobalt, other metals, granite |

|

Super Coarse |

60-70 |

Hard |

Super coarse for titanium, nickel chrome, other metals, marble, jade |

3 Types of Discs

|

Electroplated discs consist of a metal disc with a layer of diamonds electroplated onto the surface. Our electroplated discs are double sided and have either a ring of diamond coating, or a slatted or saw edge surface. These discs don’t last as long as the multi-layered discs, but are extremely efficient for a lower initial cost.

|

|

Multi-layered sintered diamond discs are just that. Layer upon layer of diamonds create the approximately 2.3 mm sintered diamond circumference ring on these discs. The thickness varies according to the diameter of the disc ordered, and ranges from 1/10th mm to 3/10th mm. These are absolutely great instruments for final or thin cutting and they last longer than regular electro-plated discs. Black marking is a non-issue because there is no metal to strike your work.

|

|

Solid sintered diamond discs are traditional, hot pressed instruments. They are solid sintered all the way to the mandrel. They last an extremely long time and do just about everything you would want a disc to do, except for final separation or creating a very thin space. The normal thickness is about 3 ½ tenths of a millimeter, and are manufactured in a variety of diameters.

|